Poka Yoke and Safe Manufacturing - How Fasteners Can Help with Mistake Proofing

Added 19.07.21

How JET PRESS supply fasteners that help with mistake proofing

The Japanese term Poka Yoke - which translates to “mistake-proofing” or “inadvertent error prevention”- is familiar to many people in manufacturing. Engineers have always worked hard to reduce preventable and costly errors in manufacturing. But it wasn’t until The Toyota Production System formalised error prevention in their manufacturing processes in the 1960’s that the name Poka Yoke became widely used.

Safe Manufacturing

Manufactures who take on board Poka Yoke in manufacturing find it delivers a range of benefits. It can reduce inspection time and lower the costs of quality control. Operators may need less training and are happier if they don’t make mistakes. There is less wastage. And improved quality control leads to greater customer satisfaction and loyalty.

Here are some Poka Yoke examples where we have worked with customers to supply fasteners that help with mistake proofing.

Does it feel right?

Different fasteners can look very similar. If you have to pick up a fastener when you are about to use it, there are several tactile signals you can give the operator to ensure they have the right part. The simplest option is to put a raised lug somewhere on the fastener when it’s made. The operator can easily feel if the lug is there or not.

We did exactly this for an engine manufacturer. Our customer manufactures a block with 6 different sizes of pipe that have to be clipped into place, including a 12mm and 13mm pipe clip. It’s very difficult for an operator to see the difference in size between these two. So we supply the 13mm clips with pips so it’s easy for the operative to feel the correct one. The clips are attached using a jig so the pips also prevent the clips from being inserted in the wrong place in the jig.

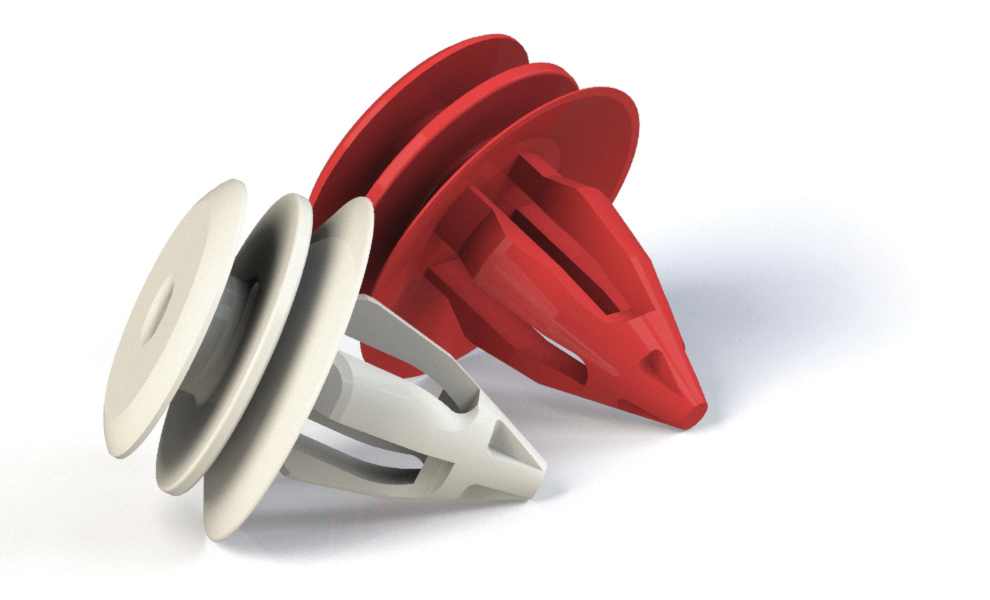

Another option is to choose an alternative texture for different fasteners. For instance, we stock more than 50 kinds of Fir Tree Clips. They look very similar, but if you specify grained heads for one size and plain for the other, operators can feel the difference.

Some manufacturing processes use a lot of different but similar looking parts. For example, one of our customers must clip a component into a car interior using 12 different but similar looking latches. They have 2 bezels, 2 different panel thicknesses and 3 varying spring forces. Look at the image and you can see we have used a combination of colours and lugs to help operatives to differentiate between the different latches.

Does it look right?

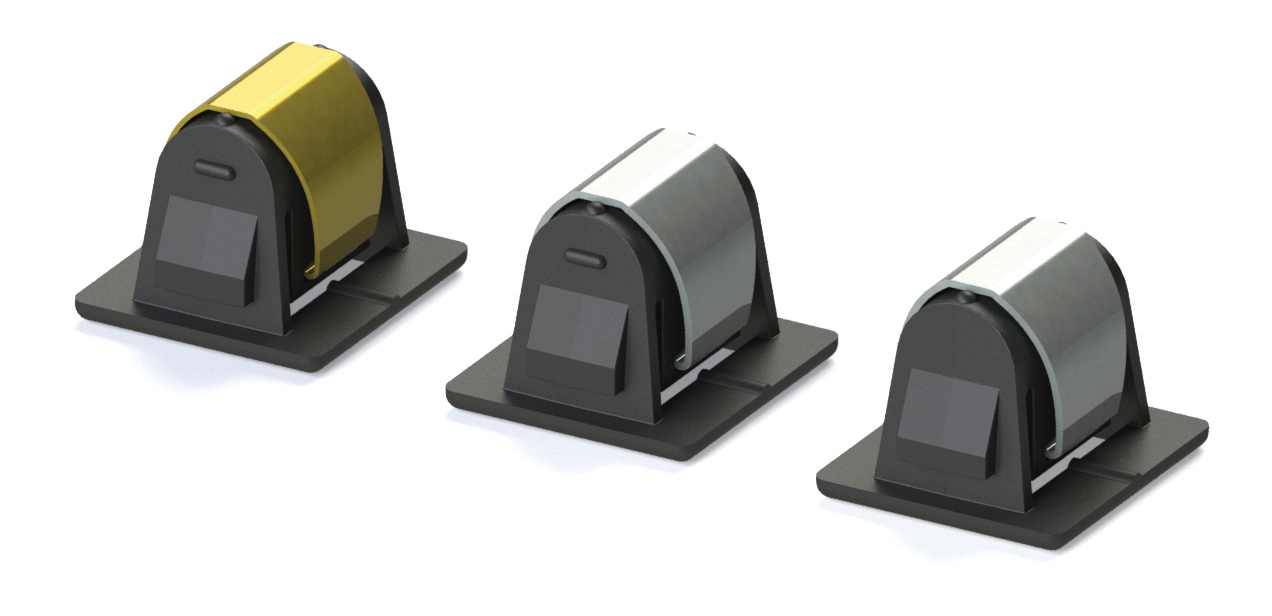

Another simple Poka Yoke technique is to use different coloured fasteners. We work with a major manufacturer who makes sofas for a range of well-known brands. We supplied them with Rivet T-Nut machines using the M8 and M6 T-Nuts. These look very similar.

The risk was that an operator could fill the hopper on the machine with the wrong T- Nut and insert them into many pieces of timber leading to expensive wastage. So JET PRESS supplies the M6 T- Nut (part no JNT061YZP) with yellow zinc plating, so they look very different from the M8 T-Nut.

When you use hose bands to attach plastic pipes it can be hard to ensure you have the right size. Again, using different colours for different sizes avoids confusion and errors. You’ll probably see this in action if you look at the windscreen washer pipes under the bonnet of your car.

Another benefit of using coloured fasteners is that they can help with robot quality control. The camera in the robot can very quickly and accurately identify if the fastener is the wrong colour.

Going beyond manufacturing into civil engineering, we supplied a customer with Lock Nuts in a range of colours. Each time a nut was removed for maintenance, it was replaced with a different colour Locking Nut. You can see at a glance which fasteners have been serviced so quality is maintained and no time is wasted doing work that’s not required.

Several of our Fasteners come in a choice of standard colours, including Cable Ties, Security Seals and Fir Tree Clips. We can supply many other fasteners in custom colours, usually subject to minimum order numbers. Our team are always keen to help you find ways to reduce errors in your business.

You can see the range of fasteners and components available on our website. If you would like to discuss your requirements please call +44 1623 551 800, email [email protected] or use our online enquiry form.

Editor’s note: This blog was originally published in 13 January 2020 and has updated to improve relevance.