10 Ways To Save Money With The Right Engineered Fastener

Added 14.10.19

The price of an Engineered Fastener is only part of the equation.

Some people only look at the price of an Engineered Fastener and choose the cheapest. Design Engineers tend to look at the bigger picture and chose the Engineered Fastener that will deliver the best lifetime value. It’s all about how you balance the price of the part, time to assemble and maintenance costs. Then factor in the reliability of the supplier and end to end technical support.

Designing in value can deliver significant and sometimes surprising returns on investment. Here are 10 examples where Engineered Fasteners delivered value, but if you want to hear about many more please give us a call.

1. Weighing up the benefits

We work with Design Engineers who are dealing with the considerable challenges of lightweighting. Lighter is better in many products.

For instance, for every 1kg of material removed from an aircraft 106kg of jet fuel is saved each year. Reducing the weight of a car by 10% can increase fuel efficiency by up to 3%. Lighter cars accelerate faster and are more manoeuvrable. Range is a big issue with the electric vehicles and the lighter it is the further it will travel on a single charge.

But lighter components may be flimsy and need more Engineered Fasteners. They are also more prone to vibration and fixing materials like plastic, carbon fibre and aluminium to steel presents challenges.

We work with Design Engineers to overcome these challenges. For instance we’ve recently supplied a bus builder with Fastmount Very Low Profile Panel Mounting Clips to attach slim, lightweight panels. Fastmount Panel Mounting Systems were originally designed for ocean going yachts and they do a great job of stopping these panels rattling in a bus.

The aero industry uses lightweight drawer slides from Accuride and replacing bolts and screws with lighter Fir Tree Clips.

2. Engineered Fasteners making it easier

It’s not just in the finished items where the right Engineered Fastener can deliver value. The assembly process can be quicker and cheaper if you use the right parts. For instance, the Fir Tree Fasteners mentioned above are very quick and easy to use and require no special tools.

One of our automotive customers had to fix a part to an Engine Beauty Cover. The original fitting required three push nuts to be inserted individually. We designed and supplied a single three point push nut and reduced the assembly time.

Another automotive client builds engines that use seven different Cable and Hose Fasteners. Each one required a different tool to install. We designed a tool with seven interchangeable heads. The initial outlay was lower and the assembly process faster.

3. Outsource the hassle

We are working with a customer on a complex civil engineering project. Firstly, we designed a bespoke Cable Management Fastener that allows cables to be added as the system is constructed. Secondly, we pre-assembled the fastener for the customer before we sent it out. It’s assembled to precise customer criteria so it can be fitted, adjusted then tightened in place. Without our solution installers would have to assemble five components on site.

We often pre assemble Swivel Clip Systems and other similar components for customers. This can significantly reduce the assembly time and therefore the on-site labour costs.

4. Maintaining the bottom line

Whatever you design, it will have to be maintained. Specifying the right Engineered Fastener will make a difference to speed, cost and safety.Larger machines are often protected with heavy guards. You can mount these on Accuride Linear Slides to make moving the guards quick and easy.

Smaller maintenance panels are often screwed in place. A screw takes time to unscrew. It can get lost. It might even be dropped into the machine. A bolt retainer will stop the screw from getting lost but a Bi-Fix Quarter Turn Fastener gives instant access. We can supply versions with more secure mechanisms to avoid accidental release.

5. Getting it out in the open

Another maintenance cost issue is the time it takes to get at key items like pumps and compressors, especially in vehicles. You can build in a solution by mounting kit like this on Heavy duty Accuride slides.

Accuride DA 4120 Heavy Duty Aluminium Slides can support a load of up to 550kg. With a combination of an Accuride 9301 Heavy Duty Drawer Slide with an Accuride 9308 Heavy Duty Drawer Slide with lever you can create a mounting that you can lock in and lock out.

In applications like trains, specialist vehicles and heavy machinery reducing down time will save a lot of money.

6. Nobody wants a burst pipe

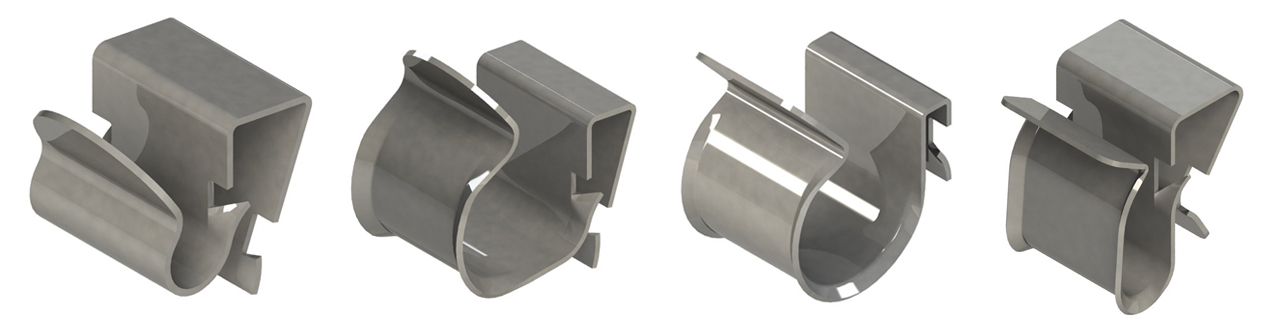

A very popular Cable, Pipe and Hose Fastener is the Pipe & Cable Clip Edge Fixing. It’s easy to use and a cost effective solution. Problems can arise when there is movement or vibration and the edge of the clip chafes against the cable, pipe or hose it retains. This will eventually result in failure of the pipe.

Specify a Pipe and Cable Clip Edge Fixing – Flared and the problem is much reduced. You can see the edge of the clip is angled away from the pipe so it’s much less likely to cause damage. We can supply a huge range of sizes, various finishes and we’re very flexible about quantities for these very useful items.

7. Cut your inventory costs

You have to stock parts to make sure production is not interrupted. There are often economies of scale if you buy in bulk. But the more inventory lines you have the more money is tied up in Engineered Fasteners. It takes time and money to manage a complex inventory.

Choose the right Engineered Fastener and you can use it for multiple applications. For instance, our Pipe & Cable Clips Edge Fixing Heavy-Duty Multifit fit a range of panel thicknesses. There are many similar ways to reduce your inventory, talk to our team about how.

8. Make a big problem into a small one

You can cut costs with creative uses of Engineered Fasteners. The Furniture Designer for a fast food chain specified Fastmount fasteners instead of glue to assemble the chairs. This cut the assembly time from 45 minutes to 15 with consequent cost savings.

But the real return on investment for the restaurant chain comes when part of a chair is damaged or worn. Instead returning the whole chair, restaurant staff order the damaged part, unclip the old one and clip on the new one.

9. More furniture savings

We have a customer who had a problem that’s common across the furniture industry. They send sofas, chairs and similar items out without the feet attached; making delivery easier and reducing damage in transit.

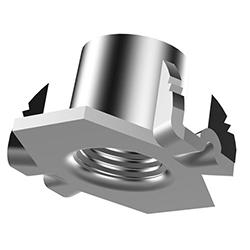

The customer has to screw the feet on when it’s delivered. But it is very easy to make a mistake screwing into a T-Nut and customers are only human. Inevitably some feet were not screwed in perfectly and when the customer sat on the furniture the T-Nut was forced out of the frame. Then the sofa had to be returned or replaced, which is a big expense.

We worked with our customer to develop a solution, based on using the right Engineered Fastener. Instead of ordinary T-Nuts they now use Rivet T-Nuts from Sigma, inserted using a Rivet T-Nut Machine. These Rivet T-Nuts have a lead in that makes it easier for the customer to get it right and it’s almost impossible to force the Rivet T-Nut out if they get it a bit wrong.

Savings on returns have easily paid for the investment.

10. Don’t replace it fix it

On a more personal level, do you go camping? Or have a caravan with an awning? Or even a jacket or boots with a zip? When zips breaks it is bad news. Especially if it’s the first day of your holiday or the jacket is your favourite.

In most cases it’s not the zip that breaks, it’s the zip pull. ZlideOn Zip Repair kits allow you to replace the pull and fix the zip. You can continue your holiday and keep the bugs out or the dog in. And that jacket gets a new lease of life. Good for you and good for the planet. For Family Packs of ZlideOn Zip Repair you can go to our sister site, Components Direct.

For more ways to make savings speak to one of our experts on +44 1623 551 800 or contact us online. Our team is always happy to help you find ways to save money by choosing the right fastener.